Longread

Pre-cooling: optimize your forced-air cooling system

Forced-air cooling is an effective method to reduce the temperature of fresh products quickly. As postharvest consultants of Wageningen Food & Biobased Research, we have experienced in practice that forced-air cooling systems are often not used optimally. We therefore share our observations and recommendations in this article.

Relevance to practice

The use of forced-air cooling systems deserves more attention. This can significantly improve your product quality, product logistics and also reduce energy consumption. One should not blindly rely on the correct installation and operation of the pre-cooling system. Even when working according to the instruction manual, the operation is sometimes still far from optimal. The saying ‘measuring is knowing’ applies to this situation. Benefits can be gained from checking the pre-cooling systems with measurements and, when necessary, adapting the work instructions or system settings.

Forced-air cooling

Pre-cooling is being used to remove product field heat rapidly after the harvest. It is a basis for keeping a good quality of vegetables, (soft) fruit and ornamentals in the cold chain. When the produce is simply placed inside a cool room, the temperature reduction of the produce will take a long time, generally days. Different pre-cooling systems are available to bring down the product temperature faster, usually within a few hours: vacuum cooling, hydro-cooling, use of ice, and forced-air cooling systems.

In this article we focus on forced-air cooling, being the most widely used method of pre-cooling. Best-known are tunnel-type fixed units where a pressure wall with fan is housed inside a cold room. The fan is used to force the cool air through the load. Canvas or polyethylene sheets (tarps) are rolled over the top of the load (and down to the floor). This directs the air through the vents of the packaging and spaces between the packaging.

Several other forced-air cooling systems exists such as small-scale portable forced-air coolers which are placed inside cold rooms, and mobile systems (containers). In this article we focus on optimizing the use of the forced-air cooling system, regardless of which type of system.

The cooling rate clearly depends on the type and volume of product. The time needed to bring the product temperature to the desired level varies from less than 1 hour (cut flowers) to 10 hours (bulky fruits). An adequate refrigeration capacity of the storage room is important, while chilling injury of the product must of course be prevented. Other important aspects that affect the cooling rate are the packaging design, the way of stacking, and airflow rate.

Packing and stacking

The kind of packaging and the way of stacking influence the cooling rate and the temperature distribution within the stack. Produce should be packed and stacked in a way that allows air to flow through equally. If you have a forced-air cooling system, we recommend to pay special attention to the following points:

- Evaluate the used packaging. A proper design of ventilation holes in the packaging is necessary to provide an effective and uniform cooling. The rate at which the temperature drops is also strongly related to the distance between the main air flow and the middle of the packaging.

- Package vents must be aligned between packaging to allow the air to flow through all packaging on the pallet. Stack in such a way that openings of packaging are in the direction of the airflow.

- Avoid blocking of vent holes in (cardboard) boxes. Vents may be restricted by produce or packaging material such as liners.

- Pallets are best fully filled, with packaging evenly distributed across the airflow path and tightly fit to each other. Too much space between the packaging would allow air to short-circuit between packaging. Use the right pallet size and leave no gaps between pallets. Be aware that four-way pallets allow short-circuiting of air.

Prevent short-circuiting of air

More often than thought, the air does not follow the intended path through the stack. Instead, it follows a shorter path than intended. There are several ways to increase the effectiveness of airflow:

- The stacked packages should fit tightly to the cooling wall, which is achieved by a straight cooling wall and straight (pallet) stacking supported with flexible foam buffers.

- In addition, materials such as foam or door seals can be used to fill gaps between the (pallet) stacks, or to close pallet openings.

- Use the tarps well to prevent short-circuiting of air. Pulling air (instead of blowing) sucks the tarp against the load and thus better prevents short-circuits.

- Pallet (forklift) openings may need to be blocked on the side and front. Foam plastic or cardboard strips can be used for this.

The warmed air coming out of the pressure wall must be cooled before supplied to the load again. This airflow is ideally directed directly to the evaporator.

Adjusting fan settings

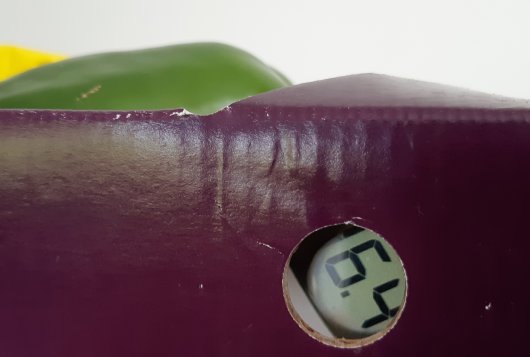

It is good practice to check the product temperature through the stack during the cooling process. It is best to measure in different places, both where the air enters the stack and leaves the stack. The complete load, including the center, needs fast cooling. It may be necessary to adjust the fan speed. More pressure difference is needed for packaging with more resistance such as with liners or (flower) sleeves.

It is not always necessary to use the maximum fan speed when other measures are optimized. A lower fan speed can save energy thanks to less use of electricity by the fan. Thermostats in the airstream leaving the packaging can shut off fans automatically when the (product) temperature has decreased to a predetermined temperature, thus saving energy. The product can then also benefit from less dehydration thanks to the reduced airflow.

Monitoring the pre-cooling process

The pre-cooling process should be monitored well in order to ensure that the cooling is achieved in the most efficient way. An uniform temperature over the entire load is a challenge. We advise to measure both air temperature and product temperature on various spots and at different time points to measure the cooling rate. In this way, experience is built up and the cooling process can be optimized.

Adapt the system settings (airflow, temperature) to the goal. How important is a fast speed of cooling? This will certainly depend on the product. Products with a relatively high perishability often needs a faster cooling. Examples are asparagus, broccoli, leaf lettuce, spinach and cherries. The target product temperature of the pre-cooling may depend also on the subsequent supply chain (temperature and time).

In addition to controlling the temperature and airflow rate, it may be wise to control the humidity. Cooling means moisture removal from the air and leads to dehydration. Products such as leafy vegetables wilt easily and can benefit from measures to reduce water loss such as humidification (see also How to influence water loss of horticultural products in storage rooms)

Our research in practice

Forced-air cooling is used by some chrysanthemum growers in order to deliver flowers at the desired low temperature. Wageningen Food & Biobased Research evaluated the cold chain for chrysanthemum in collaboration with the Dutch flower industry in the research project GreenCHAINge Ornamentals.

In this project, various measurements were made on site and then the results were used to improve the forced-air cooling systems (Wissink et al. 2018). One location did have a new cold room with pressurized walls with large high speed running fans. But measurement showed that only a very low percentage of the total pressure of the fan was effective for the pressure difference over the stack. The pressure drop was so small that it would be impossible to cause enough airflow to cool the product quickly. On the other hand, the temperature sensor near the fan measured a low temperature and thus indicated a successful cooling. It turned out that this situation was largely due to short-circuiting of air (false airflow). In fact, this temperature sensor measured the cold airflow that largely came directly from the cold storage room.

With the following adaptations we contributed to a major improvement in the actual cooling rate of these flowers:

- Correct use of the cover sheet

- Stacking packages tight against the cooling wall to prevent short-circuiting of air

- Adjustment of the ventilator to a higher air speed to reach a higher pressure drop over the stacking

- Instruction of workers

In our research facilities we have tested different situations of forced-air cooling for this specific product (chrysanthemum). These small-scale tests have given growers additional insights, for example about the cooling rate, temperature distribution, water loss of the flowers, and the influence of packaging with or without flower sleeves.

This research project has resulted in practical guidelines for the cold-chain of chrysanthemum (Wissink et al. 2017).

Conclusion

The goal of pre-cooling is to reduce the temperature of the fresh product to its optimum as quickly as is practical and economical. Forced-air cooling is a widely used method of pre-cooling. The available systems range from tunnel-type fixed units to small (portable) systems for small-scale producers. Changes in your daily practice, as described in this article, can already lead to major improvements. Therefore, the correct use of all these forced-air cooling systems deserves more attention.

Our experience is that the current use in practice can often be improved, for which we offer our services.

References

Wissink, E.B., Mensink, M.G.J., & Hogeveen-van Echtelt, E. (2018). Onderzoek naar voorkoelsystemen bij chrysantentelers legt problemen bloot. Web publication/site, RCC Koude & Luchtbehandeling. https://www.koudeenluchtbehandeling.nl/verdieping/onderzoek-naar-voorkoelsystemen-chrysantentelers-legt-problemen-bloot-91028

Wissink, E., Mensink, M., & Hogeveen-van Echtelt, E. (2017). Richtlijn koelketen Chrysant: op basis van onderzoek binnen project GreenCHAINge. (Wageningen Food & Biobased Research rapport; No. 1704). Wageningen Food & Biobased Research. https://doi.org/10.18174/402820