How to deal with fresh produce

In the postharvest life of fresh produce, it is important to know which daily practices should take place. These range from dealing with the product itself on a daily basis, understanding the behaviour of the product itself, and ensuring safety at work. The daily practices pages below describe how to best deal with the fresh product in your business. If you need immediate consultation, please contact our expert through the form below.

Daily practices in postharvest management

Conditions and product characteristics

Vegetables, fruit and flowers react differently to conditions in the chain such as temperature, ethylene and humidity due to all kinds of properties. It is therefore essential to store fresh products under the appropriate conditions to preserve the best possible quality. On this page we provide an overview of the most important product properties and target conditions for each fruit and vegetable, such as temperature, degree of ethylene production and sensitivity, and sensitivity to drying out.

Assessing packaging in practice

In practice, many different situations are encountered in which various types of packaging play a role. Below you will find points of attention per type of packaging and examples of situations in which problems are identified. In addition to packaging for the consumer, also industrial packaging and materials in the chain, used to ensure that the transport of fresh products runs as smoothly and efficiently as possible, are described.

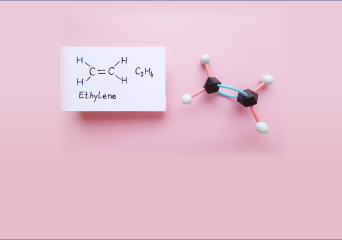

Dealing with ripening and ethylene

Ethylene is a gaseous compound also called the “ripening hormone”. It is present in the air in an extremely low concentration, often not even detectable. Yet this gaseous molecule is very important for the ripening of many fruits. Most fruits produce ethylene to start the ripening process. The effect of ethylene can be seen as positive if it leads to ripe and tasty products. Sometimes ethylene is even artificially added to regulate ripening. However, in many cases the presence of ethylene is undesirable. It limits the storage time if the fruit ripens too quickly and becomes overripe. This applies to products such as apple, apricot, avocado, kiwi, melon, papaya, pear, peach, plum and tomato.

Doing quality measurements

Extensive quality evaluations are carried out at various points in the fruit and vegetable chain. Different markets require different quality criteria. Examples of these quality criteria are a specific colour, size, firmness and sugar content. Quality can be measured non-destructively (by looking, feeling, sizing, smelling) or destructively (by cutting, tasting, grinding). Quality measurements include both external and internal properties. External quality measurements are usually focused on size and shape, colour, physiological disorders and diseases. Examples of internal quality measurements are firmness, sugar content, acidity, flavour, and disorders and diseases.

Ensuring personal safety

Storage and packhouse facilities are dynamic environments with various risks. Examples are trucks, forklifts and risks of slipping. Sometimes the packhouse is equipped with Controlled Atmosphere (CA) storage rooms with low oxygen. Exposure to low oxygen is one of the greatest dangers for persons. Remember that your safety is not only important for you. Also think about your family, your colleagues, and your organization. Always ask and follow the safety guidelines of your work location. In addition, pay close attention to the risks in your work environment. Look around and ask yourself what could go wrong?

Ensuring food safety

Food safety practices are intended to minimize the microbiological hazards associated with fresh produce. It is a very important topic: people can get sick or can even die due to food poisoning. Moreover, food safety issues can have a long-term impact on trade and consumer confidence and thus have a major impact on the fresh industry. Prevention of dirt, cleaning and sanitation are part of the daily packhouse operations. Sanitizers and disinfectants can be used, but always according to regulations. The same applies to the use of agrochemicals.

Handling living products

Harvested plant parts such as leaves and fruits are still alive. Quite some processes in plants, even when harvested, are similar to processes in animals. For example, plant material breaths: it takes up oxygen, and releases heat and carbon dioxide. It can lose water through transpiration. Also, as any living organism, the plant material still develops as it gets older. Ripening and senescence occur, and sooner or later it will die. By understanding that plants are alive, it becomes clear that one should take care of the product, in order to maintain the product quality for longer.

Storage of fresh produce

Storage takes place in different parts of the supply chain for multiple reasons. Short-term storage (hours, days) may be required for pre-cooling or when waiting for further processing or transport. Long-term storage (weeks, months) makes it possible to supply clients with products over a long period of time, even when product are not available directly from the field. To minimize quality loss during storage, the respiration and moisture loss of the products is managed by controlling the temperature and humidity in the storage room. In addition, O2, CO2 and ethylene concentrations are particularly relevant. The interaction between products and technology is a fascinating aspect of storage

Temperature management

An optimal temperature is mostly the first requirement to maintain a good quality of horticultural produce after harvest. Refrigeration is an effective method of preserving the quality of fresh produce. The cooler temperatures extend the storage life by reducing various processes such as respiration, water loss, colour change, and decay. The produce should however not be stored below their critical temperature. Chilling injury may then occur. This would result in risks on various quality problems such as weakened tissue leading to discoloration and increased risk of decay. The optimum temperature varies per commodity and should be controlled throughout the whole fresh supply chain.

Understanding quality traits of fruit

As consumers we have all experienced the joy of eating good and bad quality fruit. There is no arguing for taste, but what is “quality”? From farm to fork, specific quality traits are used to determine harvest maturity, for sorting and grading purposes, to check and predict how quality develops in the chain, for food safety regulations compliance and to estimate the use by consumers. While some of these traits can be determined without damaging the fruit, others require the fruit to be sampled.

Managing humidity conditions

In addition to temperature, the humidity of the atmosphere is an important determining condition to preserve quality of fresh products after harvest. Here we explain the basic concepts and discuss how the moisture conditions affect the product. How can it be controlled in practice?