Longread

How to control water loss of horticultural produce during storage

Water loss can lead to shriveling or wilting of horticultural produce. Reduction of water loss by practical measures may however result in other serious quality issues. How to find the right balance? The postharvest consultants of Wageningen Food & Biobased Research share their knowledge and experiences in this article. This is the first in a series of articles to support businesses in a better control of humidity in storage facilities.

Relevance to practice

For products which are sold by weight, water loss has economic consequences even when their appearance is not affected. Next to this, understanding the relation between water loss and quality can help you to optimize the conditions in storage facilities. For example you can target a maximum and/or minimum water loss of the produce in storage.

Acceptable water loss of horticultural produce

An optimal temperature is mostly the first requirement to maintain a good quality of horticultural produce. Humidity is the second condition of importance in storage rooms. The relative humidity in storage rooms can have various effects on quality. Shriveling and wilting are well-known issues. They are the consequence of moisture loss from the fresh produce to the dryer environment. Moisture loss, or water loss, means weight loss.

A little water loss is not harmful for the quality. It does not lead to visible symptoms. Some water loss may even be necessary to prevent fungal growth or tissue browning of fruits.

The permissible water loss differs per commodity. Apples start to show shriveling symptoms when they have lost approximately 4-5% of water. This should be counted from the moment of harvest. Spinach easily shows wilting. Pears with elongated necks (‘pear-shaped’) start showing symptoms above 2% water loss. A commodity such as squash can tolerate a high water loss before any symptoms occur.

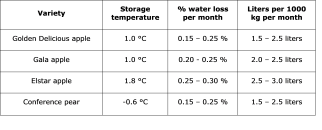

Some water loss may be necessary to prevent physiological disorders or fungal attacks. This also varies per commodity and even per variety. The next table shows some examples for long-term storage of apples and pears (Table 1). It includes the maximum but also the minimum recommended water loss. We have based these criteria on our research and practical experiences.

A very simple method to measure the water loss is to measure weight loss: 4% moisture loss equals 4% weight loss. Measuring the % weight loss from the moment of harvest gives insight in the risk of wilting or shriveling. Another method is used in closed Controlled Atmosphere (CA) storage rooms. In these rooms, the quantity of drained water from the refrigeration equipment can be used to estimate the moisture loss of the produce. The correct interpretation of data is crucial here. We will explain this method in the long read on Measuring Water Loss.

Fungal diseases

Fungal diseases occur on a wide range of horticultural produce. These diseases include Botrytis (see figure below), Fusarium, and Anthracnose. When humidity in the room is high, fungal growth can develop more rapidly. This may stay limited to small superficial infections. But it can also lead to completely rotten produce. The diseased produce easily releases water. Due to this extra supply of water the humidity in the room will increase further. A diseased batch can thus create favorable conditions for fungal growth on other still sound batches in the same room.

Although humidity management plays a role in the control of diseases, we want to emphasize that other factors are usually of much higher importance to prevent diseases. Apply good pre-harvest practices, good harvest maturity and prevent damage during transport. And check that the temperature in the storage room is correct!

Internal disorders

An increase in ambient humidity close to fruit surfaces may favor the development of internal browning. This is called a physiological disorder. Examples are tissue browning in Gala apples and Conference pears. Some extra evaporation can be advantageous as prevention.

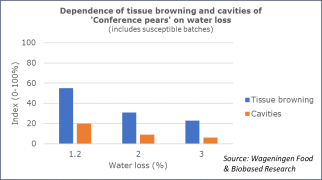

Within our Postharvest research program we work on practical solutions. Conference pears harvested late can be susceptible to the development of tissue browning and cavities in Controlled Atmosphere (CA) storage. In one of the experiments, we stored these pears in different research units which imposed either 1,2%, 2,0% or 3,0% water loss during 9 months storage. Interestingly, the research showed that the risk on this disorder can be reduced by increased water loss (see figure below).

Skin disorders

Signs of wilting and shriveling are well-known for many horticultural crops. The symptoms often go together with less gloss. There are also other skin disorders which have a link with humidity in the storage room. Superficial scald is a skin disorder of apples and pears (see figure below). It appears as a diffuse skin browning. Although it increases during shelf-life, the cause lies earlier in storage. The fruits produce a volatile named alpha-farnesene. This accumulates in the wax layer and is the basis for the skin damage in later stages. Lower relative humidity can stimulate evaporation of this volatile and thereby reduce the risk on skin damage.