Banana

Postharvest management of (dessert) banana knows many aspects. Please select the page of your interest below. For bananas, we have gathered information about the international supply chain of the banana. Next, we focus on the detailed steps along the supply chain. We start with discussing the harvest practices for bananas. We continue with proper packhouse practices and transport practices. Bananas frequently undergo ripening, which is also discussed. The last step in the supply chain is the retail. Also the needed retail practices for bananas are described. The last two banana pages deal with banana quality and frequently occurring disorders and diseases. If you need direct consultation on proper postharvest management of bananas, please contact our expert through the contact form below.

Postharvest points of attention for banana

The banana supply chain

Practices in each step of the fresh chain have a great influence on the postharvest quality and shelf-life of fruit and vegetables. This also holds for (dessert) banana. Harvest and cold chain must be well managed to reach the expected banana quality by the consumer. By using appropriate harvest processes and chain conditions, quality can be maintained longer and shelf life can be extended. Failure to follow these processes may result in a high degree of loss or deterioration of the product to a lower quality class. Every step in the chain is important for success later in the chain.

Harvest practices for banana

Proper picking is a precondition for being successful in the rest of the supply chain. The performance of the harvest crew is therefore critical to deliver a good quality product. First of all, picking at the right maturity is important to get the bananas in good (green) condition on the long-distance market. The harvest and further handling must be done carefully to avoid bruising and other damages to the product. The use of clean and suitable materials such as sharp knives and a cable way system in the plantation also serves this purpose.

Packhouse practices for bananas

Packhouse practices include the activities from the moment the products arrive at the collection station or packhouse to the moment of transport to the intended market. Dividing the bunch into smaller units, washing, sorting and packing are among the main activities. Good packaging is a requirement to maintain a good quality of banana throughout the rest of the supply chain. This also applies to good temperature management. Furthermore, proper cleaning and sanitizing of building and equipment is part of good packhouse practices.

Transport practices for banana

Transport of fresh products like bananas generally takes place in (refrigerated) trucks, reefer containers, or by plane. Checks and proper loading are always important to maintain good (temperature) conditions for the product during transport. For fresh products, refrigerated transport is often necessary. Trucks and reefers can maintain a low temperature, but do not have enough cooling capacity to quickly lower the product temperature. During transport and waiting periods, the load must be well covered to protect against dust, sun and rain. Careful driving and handling are essential to prevent damage to produce from mechanical actions.

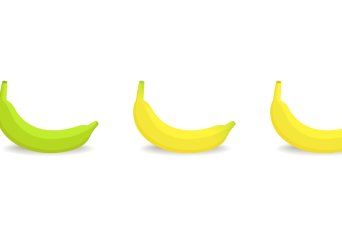

Controlled ripening of bananas

In order to deliver bananas at the desired stage of ripeness to retailers and ultimately to the consumers, controlled ripening takes place. Controlled ripening takes place in so-called “ripening rooms” or “banana rooms” in special ripening facilities or in the distribution centre. In these rooms, ethylene is released at a controlled temperature and humidity. Experts adjust the details of the ripening program to the maturity of the batch and the planned delivery to retail

Retail practices for banana

Improved retail practices can lead to a higher quality of bananas and improve customer satisfaction. For the highest freshness on the shelf and to minimize waste, 'first-in first-out' management may be the best strategy. However, quality inspections may lead to other decisions. The staff must be well trained in handling the different types of fresh produce. They must realize that fresh products such as bananas are very susceptible to handling damage and to unfavourable conditions such as too low or too high temperature.

Banana quality

Quality of banana is defined by several quality attributes. The most important are appearance, colour, texture and flavour. Appearance and colour are examples of quality attributes judged on the outside, whereas texture and flavour are internal quality parameters. The quality attributes are influenced by variety, preharvest factors, harvest practices and postharvest handling. Determination of fruit quality provides an important indication of the remaining storage potential and shelf-life.

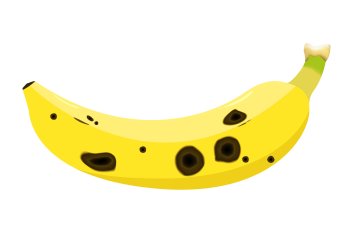

Banana disorders and diseases

Good quality bananas are free from diseases and disorders. Customers are not willing to purchase fruit presenting rots or damaged skin. Furthermore, fruit that looks good on the outside but presenting brown flesh on the inside will not lead to happy customers. There are dozens of different diseases and disorders, which are not always easy to recognize. A good diagnosis of the fruit’s health is important. By recognizing the symptoms of a disease or disorder, it can be linked to the cause. If you know the cause, you know what measures can be taken to prevent the disease or disorder in the future.

Research insights for postharvest management of banana

In our applied research, we study postharvest management of many fresh products. On this page, some results from our research relevant for banana are indicated.