Research Results

Mango internal defects and quality

In GreenCHAINge an innovative “smart chain” is being developed. Overall goal is to improve the intrinsic quality of the product on the shelf. For mangoes, the detection of internal defects is important.

Objective

Experiment and Results

More than 3000 mangoes shipped from Brazil were measured on internal defects in the period between November 2016 and January 2017. These measurements showed that pulp browning correlates with

- Decreased firmness.

- Increased internal dark yellow color.

- Higher ripening temperature.

Additional experiments showed that pulp-browning correlates with increased storage time.

In a second experiment, mangoes were cut into 1 cm2 mango cubicles to mimic “cut mango pieces”. This experiment showed that an increase in internal breakdown correlates with browning of the mango cubicles.

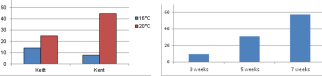

Figure left: Percentage of internal breakdown increases at higher ripening temperature, for both cultivars Keitt and Kent.

Figure right: Percentage of internal breakdown increases upon longer storage (respectively 3 weeks, 5 weeks or 7 weeks at 16 °C).

Conclusion

Internal pulp browning is mostly observed in ripe mangoes, where temperature and storage time are positively correlated with the internal breakdown of cell tissue.

Understanding of the factors that trigger internal defects / browning can help to improve decision making in the current logistics chain, thereby minimizing practices that contribute to the problem.