Research Results

Fruit quality prediction

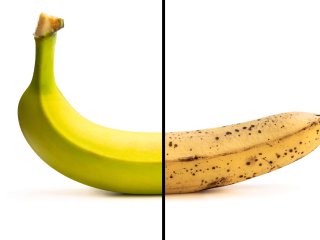

In the project “Future sensors and digital twins to improve perishable food quality during distribution” an application programming interface (API) is developed to predict fruit quality based on actual recorded storage and transport conditions.

For more information about the project “Future sensors and digital twins to improve perishable food quality during distribution” click here.

Objective

Results

With the developed application programming interface a prediction of fruit quality (remaining storage life) for a fruit batch is calculated, using recorded storage/transport conditions of a certain reefer container and using physiological product characteristics as input. The conditions include recorded temperature, relative humidity, oxygen and carbon dioxide levels over a certain period. The API can also provide warnings e.g. with respect to risks on chilling injury and oxygen or carbon dioxide damage. The interface is available for many different fruit types, amongst others avocado and banana.

Relevance to industry

Nowadays many conditions during storage and transport of perishables are recorded, while the product quality itself is more difficult to monitor through the whole chain, especially in a reefer transport. A quality prediction using specific product parameters in combination with actual recorded storage and transport conditions is a step forward towards more reliable predictions. These are valuable to use as support for decisions in the supply chain.