Longread

Quality progression and its modelling

After harvest, the quality of the (fresh) product does not remain constant. If only this were the case! Sometimes it starts with ripening, but then the quality of the product will diminish, eventually becoming unacceptable for consumption. In short, products are "alive" and constantly changing. These are processes that continue that have already started before harvest. There are also processes that start just after harvest. All these processes together are called quality progression. Sometimes products are locally sourced (think tomatoes, apples and pears) but often also from the rest of the world (think bananas, mangoes and avocados). In addition, there are often many different varieties (think Kanzi and Elstar apples) and it sometimes matters what season you buy produce in (think strawberries which are sweeter in the summer). How does the quality of produce change after harvest and during all the steps present between producer and consumer?

The Netherlands is a major producer of many horticultural products that are exported after harvest, while we are also a focal point for the import and re-export of, for example, flowers and tropical fruits. We also live in an increasingly digital world where more and more can be and is measured with sensors that are often connected to the Internet. Think of sensors that measure growing conditions, the status of the product at harvest, temperature and humidity during (sea) transport, but also, for example, how much respiratory gases the products produce. Can we combine knowledge about processes that affect product quality with sensor data? Can we use the revolution in artificial intelligence combined with sensor data to track changes in quality? Yes, we can!

We can and want more and more. We not only want to understand and describe quality trends, but also to predict them. And that is difficult but also offers many opportunities, because we can then intervene. Suppose sensors on board a ship bound for Europe indicate that a batch of avocados is ripening rapidly. Then we can use quality progression models to examine the effects of sailing faster, for example, or to adjust storage conditions. Perhaps that is not enough, and the boat can choose a different arrival port to avoid food losses and waste. If, for example, adjusting the storage temperature does suffice, it may ensure that consumers find great avocados in the supermarket. Win-win!

What is modelling anyway? And what types of quality models exist? Below, we will give a (not exhaustive) overview of concepts and models. We will also indicate what is possible, and what may not yet be. In addition, we discuss the latest trend, digital twins.

What is modelling?

That depends on who you ask... Modelling is usually based on experimental data, from the lab or just from practice and are product specific. So a model for apple quality cannot be used for mango. Data from different factors that are correlated can be used. Often statistical analysis is the start. Statistical analyses try to identify the influence of different factors on the course of quality. Kinetic modelling focuses on describing (parallel) processes based on general laws. Other models rely on (machine-learning) techniques that connect inputs and outputs without the relationships being directly visible (black-box models), and sometimes there are combinations of the two (hybrid models). In all cases, models are intended to understand product behaviour, describe behaviour, and if possible, predict behaviour. The latter is the most difficult.

Models represent knowledge about the product. Because there are very many factors, models are often complex. With kinetic models, the processes are often simple, but the interactions are complex. With black-box models, you can often impose complexity, but with limits, otherwise you are over-fitting. Simulations and calibrations are needed, as with weather models, to be able to predict future quality and already anticipate it in the present, for example by adjusting storage conditions, choosing other marketing channels or adjusting prices. Models (simulations, calculations, predictions) therefore play a role (or can play a role) in decision support, and in the longer term in the quality-controlled chain: a chain that is steered by (prediction of) product quality. The organization of such a chain, by the way, requires much more than a model alone; the chain will also have to be set up for quality control, for example by implementing many/more measuring points and performing more permanent measurements (data acquisition) and training of personnel.

Modelling shelf life

Shelf life is the time a product has a marketable quality according to predefined criteria. That time is influenced considerably by temperature (which is why we keep many products in the refrigerator), but also by what a consumer considers acceptable (a few brown leaves on a rose, is that still Ok?). It is possible to combine simple or also more complex quality decay models with consumer limits to indicate shelf life as a function of temperature. The attached figure shows this for two products (lettuce and tomato).

![Example of model output of expected shelf life for lettuce and tomato and various storage temperatures [2].](/upload_mm/e/9/6/4963d8f2-bf2f-421e-a6ff-54133898e2e7_model%20mango_322x200.png)

For lettuce, the lower the storage temperature, the better (but don't let it freeze!). For tomato it is different: there is a maximum at about 14 °C. The background is that two models of quality are combined here, one for aging (the colder the better, just like for lettuce) and one for cold damage (the colder the worse). This works very well, and model parameters for this model are available for very many products [2]. This gives insight into shelf life as a function of temperature and thus the optimal storage temperature, and is useful in the chain because it is easy to make a dynamic version of it. By the way, quite a lot of products are cold sensitive, especially those originally from tropical regions.

Modelling firmness of tropical fruit

Bananas, mangoes, and avocados are often in transit for weeks to Europe, and therefore are often picked unripe, followed by a ripening treatment, with or without a gaseous ripening hormone, ethylene. The following figure shows the data and model simulation for hard and soft mangoes with and without ethylene.

![Example model predicting firmness development of various mango batches, without (left) and with (right) ethylene, at different storage temperatures [3]](/upload_mm/1/2/c/3a581b01-91b2-4576-814e-63c24e672b86_mango%20kwaliteit%20verloopScreenshot%202023-11-21%20125314_322x322.png)

The (kinetic) model is based on a combination of three processes related to cell wall degradation by enzymes produced by ethylene in the fruit or added during storage [3]. There are more such models, for other tropical fruits. The practical application is not there yet, because one of the parameters, the ethylene sensitivity per batch, is unknown right now. That could well change if the ethylene concentration can be measured during transport. And that is almost possible. We have a system that can automatically aspirate air during transport, and sensors that can measure ethylene and transmit it via the Internet are under development and testing.

Modelling firmness of pears

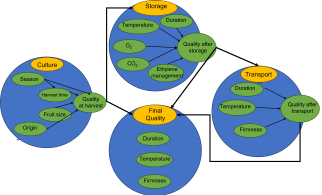

For modelling pear firmness, another method based on machine learning using a Bayesian network was used [4]. The Conference pear model that was developed calculates probabilities that certain (un)known factors such as, for example, season, origin, picking time, application of ethylene inhibitors, storage and transport time, display conditions, lead to a certain product quality at different moments in the chain. The figure shows a fragment of a Bayesian network (in Dutch) where factors affecting hardiness are represented with probabilities (of stochasts). The values of the stochasts are learned from data.

Additions can be made by working with experts to provide estimates for those records for which data are not available. Using the Bayesian network, scenarios can be calculated, such as determining the probability of a particular firmness at different stages in the chain. Based on these outcomes, adjustments can, for example, be made in storage conditions, which can then be recalculated. Also, based on this information, one can choose, for example, to change sales channels or to re-sort. Sensitivity analyses can be done with a Bayesian network to gain more insight into the effects of storage conditions and concepts, and cultivation characteristics on subsequent quality. Based on knowledge gained in this way, more effective cultivation and storage methods can be used in the future to improve pear quality [4].

Modelling storage in under controlled atmosphere conditions: example broccoli

A lot of produce is stored. Sometimes they are stored for a very long time, such as apples and pears (year-round!) and reduced oxygen and increased carbon dioxide concentrations are used to reduce respiration, or in other words, the product is put to sleep. It is possible to combine models. In the figure you can see a combination of a respiration model and a quality gradient model for one of the healthiest substances in broccoli, glucosinolates [5]. The more glucosinolates the better for product quality. This particular model study indicates that packaging broccoli in a package that regulates oxygen and carbon dioxide concentrations (MAP) may make sense for healthier broccoli in the supermarket. Respiration models are also regularly combined with quality-decay models, focusing on firmness of a product. These can be used to look at scenarios and decide how long and when batches can be kept to get to market with sufficient firmness.

![Level of glucosinalates in broccoli at different O2 and CO2 levels during storage [5]](/upload_mm/6/a/b/a431e8ec-8fe7-4bc2-894e-ea3f1137799c_Gecombineerd%20modelresultaat%20glucosinolaten%20in%20broccoli_322x323.png)

Digital twins

Combining models is the modern trend, for example, in a digital twin. A digital twin is a virtual representation of a particular product and is linked to the real product by sensors. Statistical and data-driven twins quantify how quality loss of fresh horticultural produce occurs by understanding patterns in the data that can explain why quality loss occurs. This can be done by combining models such as those based on underlying physical, biochemical, microbiological, and physiological processes. Digital twins provide useful data for exporters, retailers, and consumers, such as the remaining shelf life of each shipment, on which logistical decisions and marketing strategies can be based. Twins also help diagnose and predict potential problems in supply chains that will reduce food quality and cause food loss.

For more information on digital twins: Digital twins, what are they? and Digital Twins and Innovative Twins in Supply Chains

The current state of models: what can we do and what not yet?

In the future, sensors are going to play a crucial role, especially if they are linked to the Internet to transmit "real time" data about products being transported. That will provide large data sets. Big data and AI (machine learning) are certainly going to play a role in further understanding quality evolution, likely in combination with physiological and physical models, the hybrid models, brought together in digital twins. This will provide enormous opportunities to track batches of produce, whether flowers or fruits, and intervene to prevent food loss and ensure quality preservation, regardless of where the produce comes from! The future is complex, but mostly bright. That means new sensors, experiments in controlled environments, but especially data from the field (big data) and the creation of hybrid models. If you would like to know more about the possibilities of incorporating modelling into your chain, we would be happy to assist you!

References

[1] Van de Geijn, F., Van Schaik, A., Verschoor, J., 2006, Conference bewaring. Een uitgave onderdeel van KwaliCon.

[2] Tijskens L.M.M., Polderdijk, J., 1996. A generic model for keeping quality of vegetable produce during storage and distribution. Agricultural Systems. 51, 431-452.

[3] Schouten, R.E., Fan, S, Verdonk, J.C., Wang, Y., Mohd Kasim, M.K.1 Woltering, E.J., Tijskens, L.M.M. 2018. Mango firmness modeling as affected by transport and ethylene treatments. Front. Plant Sci., 20.

[4] Rijgersberg, H., Van de Geijn, F., Van Schaik, A., Willems, D., Hogeveen, E., 2018, Grip op kwaliteit van Conference-peren met behulp van een Bayesiaans netwerk. GreenCHAINge G&F DP5 Export peren verre bestemmingen.

[5] Schouten, R.E., Zhang, X., Verkerk, R., Verschoor, J.A. Otma, E.C., Tijskens, L.M.M. van Kooten, O. 2009. Modelling the level of the major glucosinolates in broccoli as affected

by controlled atmosphere and temperature. Postharvest Biology and Technology 53, 2009, 1-10.

[6] Defraeye, T., Shrivastava, C., Berry. T. Verboven, P., Onwude, D Schudel, S., Bühlmann, A., Cronje, P., Rossi, R.M. 2021. Digital twins are coming: Will we need them in supply chains of fresh horticultural produce? Trends in Food Science & Technology, 109, 245-258.