Longread

Water loss of horticultural produce: Measurements in (CA) storage rooms

Controlling the water loss of horticultural produce is important for quality preservation. By measuring the water loss yourself, you can make the right decisions. The postharvest consultants of Wageningen Food & Biobased Research share their knowledge and experiences in this article. This is the second in a series of articles to support businesses in a better control of humidity in storage facilities.

Relevance to practice

Controlling moisture loss (water loss) during storage can keep the quality of fresh horticultural products at a high level. How much is the water loss of products in your storage facilities anyway? There are several methods for estimating water loss. A good understanding of the factors influencing these measurements is crucial. Only then can the data interpretation be performed properly. This way you can make better decisions about appropriate follow-up actions. In this article we pay special attention to the collection of condensed (defrost) water from the evaporator in Controlled Atmosphere (CA) rooms. The amount of water collected can indicate the moisture status of the product in the room. But only on condition that obtained data are correctly interpreted.

Several methods to estimate water loss

Methods of monitoring water loss do not always have to be very advanced. Also looking and feeling gives you an impression of the moisture status of the products. We recommend checking product samples regularly. Start by checking the moisture status at the beginning of storage and keep checking during storage.

Water loss can be quantified relatively easily by measuring weight loss during the storage period: 1% weight loss corresponds to 1% water loss. These weight measurements can give you many insights, for example by measuring in different places in your storage room.

We describe two other methods in more detail: the use of temperature and relative humidity (RH) and the collection of water from the evaporator in CA rooms.

The use of temperature and relative humidity (RH)

You get roughly an indication of the degree of water loss with measurements of temperature and RH in the storage room. With temperature and humidity, the vapor pressure deficit (VPD) can be determined. At a low temperature and a high RH, the VPD is low. Then you can assume a low evaporation rate of the products. However, the measurement of high relative humidity (>90%) at low temperatures is generally difficult, measurement deviations easily occur.

An important point, which is often overlooked, is the temperature difference between the products themselves and the environment. It really makes sense to measure product temperature in addition to air temperature. When a product is clearly warmer than its environment, it releases water more easily. This situation occurs when warm (field) product enters the cold store. Therefore, a fast reduction in product temperature can contribute significantly to less water loss.

In addition to temperature and RH, the water loss also depends on other parameters. Specific characteristics of the batch of horticultural products influence the water loss. The surface-to-volume ratio is of course important, but also the cuticle resistance and boundary layer resistance. The cuticle is the waxy layer that covers plant organs. It serves as a barrier against moisture loss from leaves, fruits and other plant parts. The boundary layer is a thin layer of air with high humidity over the commodity’s surface. This also slows water loss.

Measuring water loss in CA storage rooms

In closed CA rooms, measuring condensed (defrost) water from the evaporator can provide valuable information. It may indicate too low or too high water loss of the product. But a good understanding of the factors that influence these measurements is crucial. Because only then can the interpretation of data be done properly, which is necessary to decide whether follow-up actions are necessary.

The below paragraphs are devoted to this measurement of condensed (defrost) water from the evaporator.

Measuring water loss in CA storage rooms: The principle

Water vapor condenses on the cold coils of the evaporator in the cooled storage room. The resulting increase in vapor pressure deficit stimulates the evaporation of the water from products in the room. The equilibrium vapor pressure is then re-established. In this simplified representation, the amount of condensed water on the evaporator is equal to the amount of water loss of the product. This condensed water on the evaporator can be drained (after defrosting) and the amount of liters measured.

But for the correct interpretation of the measured liters, we need to know how important other influencing factors are. Think of condensation on other cold surfaces in the room. Or water adsorption by dry materials in the room, such as wooden bins or pallets.

Measuring water loss in CA storage rooms: Technical installation

The condensate drain has a number of special features. This is to ensure the gas-tightness of the CA room and to prevent drip water on the products in case the drain becomes clogged. The condensed (defrost) water is collected per room in a vessel or passes an automatic electronic water meter. This is done separately for each evaporator in order to be able to determine specific behavior per evaporator. An abnormal measurement may indicate suboptimal function or ice formation in the specific evaporator.

Measuring water loss in CA storage rooms: Registration and interpretation

It can be quite difficult to translate the volume of the collected water into the amount of water loss of the products. It is important to realize that there can be several other sources of water in a storage room: moistened floors, water content of (wooden) bins, active humidification and entrance from warm (humid) outside air. The latter could happen via the CO2 scrubber system or through air exchange. In open rooms (before or after the CA period), the influence of exchange with fresh air is too great. Water measurements are then not useful to indicate water loss of the products. The water measurements can start after the CA room is closed.

The weather plays a role. An increase in atmospheric pressure leads to the entrance of warmer (moist) outside air in the room. This can lead to more water. We can even recognize rain periods in the measurements. In periods of cold weather with frost, when the cooling actions are less, the measured amount of water can be small.

Due to these influences, daily fluctuations in the amount of water drained are quite common. Daily review shows too many fluctuations to draw a good conclusion. Therefore, it is recommended to analyze data over a period of 1 week.

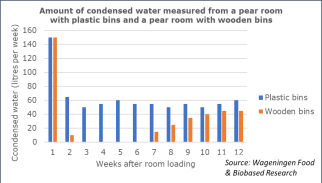

Within our Postharvest research program we work on prediction and better control of moisture loss of a range of horticultural products. In a previous study, we compared two similar pear rooms. Plastic bins were used in one room and wooden bins in the other. The amount of condensed (defrost) water from the evaporator was measured weekly (Figure 3). The amount of water was very high for both rooms in the first week after room loading. But because the rooms were still open, these initial measurements were pointless for estimating the water loss of the product. In the weeks that followed, a clear difference was found between the rooms. There was no water drained from the room with the wooden bins at all. However, this does not mean that the pears had not lost water. The wooden bins were able to absorb a significant amount of water until they were saturated. Later in storage, the measured condensed water from this room gave a useful indication of the loss of water by the product.