Longread

Humidification in storage, necessary or not?

Water loss of fresh products causes quality loss such as wilting and shriveling, and it also means loss of marketable weight. Therefore, the commercial impact can be significant. The water loss of fresh produce is usually sufficiently limited by low temperature and high relative humidity. Humidification in the storage room can make a positive contribution. But also consider the possible downside of humidification on product quality, such as a higher risk on mold growth. Different types of humidification systems are being used. In this article, the postharvest consultants of Wageningen Food & Biobased Research describe the various systems and discuss some of their advantages and disadvantages.

Relevance to practice

Often, when the storage room is optimized by its insulation, cooling capacity and air circulation, not much moisture is removed from the storage room and humidification is probably not necessary. Packaging can also contribute to the goal of limited water loss. In our previous articles we have given practical tips for this. If these measures are not effective enough, humidification systems can indeed be used as an additional tool.

Cool-down phase versus storage phase

The need for humidification may depend on the storage phase. We can distinguish between the cool-down phase, when warm products from the field enter the room, and the subsequent storage phase after the product has cooled down.

During the cool-down phase, the long cooling time can cause a significant amount of moisture to condense on the cold evaporator coils. Thus reducing water vapor in the air. If products are supplied in dry wooden bins, the wood can absorb a significant amount of water vapor. For example, apples and pears can lose about 0.7% of water due to storage in dry wooden bins. In this early storage phase, the humidification can bring in the water that is removed from the air due to frequent cooling and wooden bins.

In the next storage phase, once the product has cooled down to the desired storage temperature, the number of hours per day that the refrigeration runs decreases. At this stage the vapor pressure of the air is more stable and the need for humidification is usually less.

Different systems are used for (fruit) storage. A division can be made in centrifugal systems, ultrasonic systems, and nozzle systems.

Centrifugal humidification systems

The centrifugal humidification systems use a spinning disk to atomise the water, creating a fog. A built-in fan spreads the fog in the storage room. You see an example on the photo below. The system is simple, economical and easy to maintain. It functions well in rooms with temperatures above zero degrees. Due to its high capacity and relatively large droplet size, this system is mainly used in the cool-down phase.

Ultrasonic humidification system

Ultrasonic devices produce a fine fog. The photos below show equipment with an ultrasonic humidification unit inside. It uses high-frequency vibrations. A transducer just below the surface of the water works to let the water to escape from the surface in the form of a cold fog. An airflow brings the fog into the room.

When products (e.g. pears) are stored below 0 degrees Celsius, the ultrasonic equipment is located outside the room to prevent water from freezing and for easier maintenance. The fog is brought into the room via a tube or piping system. These systems usually bring the fog at the front of the evaporator. During operation, the evaporator fans blow the mist into the room. The droplet size is very small, below 3 µm or even below 0.5 µm. Some of the advantages of the ultrasonic systems are this small droplet size and the low energy consumption. It is mainly used in the storage phase. Challenges are the capacity and life span of the ultrasonic unit.

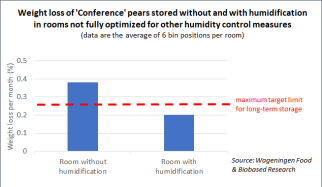

Within our Postharvest Research programme, we work on ways to control moisture loss of horticultural products. In a previous study we tested a new ultrasonic humidification system. For this we worked together with the manufacturer and a commercial storage facility. As part of the study, we filled two identical CA rooms with Conference pears in wooden bins (without plastic foil). One of the two rooms was equipped with the humidification system. Indeed the weight loss was significantly reduced in this room and remained under the maximum target limit for long-term storage (see Figure 4). The red line in the figure represents the maximum weight loss to maintain the quality of Conference pears in long-term storage. The pears in the room with humidification remained below this limit. The pears in the room without humidification lost too much water, which compromised the quality of the pears.

Indeed, an important attention point was the shriveling at the pear necks. This was hardly visible when the rooms were opened, but clearly increased during the following shelf-life period. The humidification system clearly reduced the shriveling.

Together with a wide range of other studies and practical observations, we can conclude that humidification can be useful in certain situations. However, this should be assessed at company level. In the above study, other measures to reduce water loss would also have been effective.

Nozzle humidifcation systems

Another group of humidification systems make use of nozzles. Thus a fine water spray is created. These systems can be based on water under high pressure or based on compressed air.

For high-pressure nozzles, water is pressurized with a high-pressure pump. Pressurized water is transported to high-pressure nozzles, where the water is atomised. In the case of compressed air nozzles, the water is being atomised with compressed air. The spray nozzles are supplied with water and compressed air. Low oxygen air or nitrogen can be used for Controlled Atmosphere rooms.

These nozzle humidification systems often have a central pump in the storage facility and a valve per room. One or more nozzles are then placed near the evaporator’s outgoing airflow. Such a system can have a high capacity, which can be especially useful during the cool-down period. And one system can serve multiple rooms, so has relatively low investment costs per room for large storage facilities. But the droplet size is mostly larger than the ultrasonic system, which makes distribution in the storage room more difficult.

Humidification, necessary or not?

Is humidification necessary? When considering whether humidification is necessary, the commodity and variety play a major role. This also applies to the duration of storage. We can conclude that humidification can be useful in certain situations. However our consultancy team need to assess on company level whether other measures can be improved in the first place. Think of optimization of the refrigeration system, air circulation, bin stacking and packaging. In cases where humidification is beneficial, there is a choice between different humidification systems. This depends, among other things, on the storage phase, the desired droplet size and the required humidification capacity.