Longread

How to influence water loss of horticultural produce in storage rooms

Water loss of fresh products causes quality losses such as wilting, shriveling, loss in texture and loss of fresh appearance. It also means loss of saleable weight. Fortunately, we can control this water loss to a reasonable extent. The postharvest consultants of Wageningen Food & Biobased Research provide practical advices in this article.

First of all, the storage temperature plays a major role. In general, at lower temperatures, the evaporation rate is reduced. This is one of the reasons to store at low temperature. Water loss can further be reduced by high relative humidity (RH) of the air. A high RH between 85-98 % is common to prevent desiccation. On the other hand, too high RH can lead to fungal and bacterial growth, and even to physiological disorders.

Relevance to practice

Control of water loss after harvest is necessary to maintain good product quality. This is one of the important objectives that must already be taken into account when building storage facilities. In this article, we also provide practical tips for existing storage rooms. The water loss in storage rooms can be controlled by optimal use of the cooling capacity and cleverly controlling the refrigeration. If this is not enough to limit dehydration, wetting floors, alternative packaging or humidification systems may be considered.

New construction

The design of a new storage facility includes choices that affect the product quality. This also applies to quality in terms of water loss. Here we explain two choices that affect water loss: the refrigeration system and the insulation of the room.

The refrigeration system shall be designed in such a way that it provides sufficient cooling capacity. The required cooling capacity is especially high when warm products from the field enter the room. Rapid cooling is then important to slow down processes such as ripening, senescence and fungal attack. In addition, when a product is clearly warmer than its environment, it also releases water more easily. Therefore, a rapid reduction in product temperature can contribute significantly to less water loss.

Once the product has cooled down, it should be kept at the desired temperature. The more stable the temperature, the lower the moisture loss will be. Minimizing the hours of cooling will also reduce the condensation on the cooler surface. The number of hours per day that the refrigeration should run depends on cooler capacity and on the amount of heat to be removed. To reduce the amount of heat that needs to be removed from the storage room, you need to pay close attention to all heat sources including the insulation of new construction. After all, an important heat source during the storage phase is the heat transmission through walls, floor and ceiling (radiation heat). Remember that cooling means moisture removal from the air. This process occurs when air passes the cold evaporator coils and cools down below the dew point temperature. The water vapor condenses on the cold coils, and can be collected and drained via a drainage system.

Technical settings during storage

You can influence the water loss of products in rooms in use by changing room settings. Main points, which can be controlled are the following:

Optimize the settings of the refrigeration system

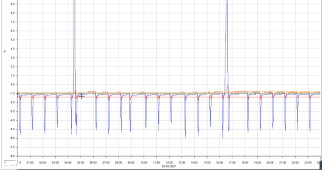

The number and length of cooling actions can be used to steer towards less or more water loss. More efficient use of cooling capacity will lead to less cooling hours. And thus reduces dehumidification. When sufficient cooling capacity is available, short cooling actions can be set to effectively cool and limit weight loss. The even spread of the cooling time over 24 hours will lead to more stability in the product temperature. When there is too much time between cooling actions, this stimulates more variations in product temperature and negatively affects moisture loss.

Reduction of heat sources

The required refrigeration time can be reduced by controlling the heat sources in the room. The importance of good insulation was already mentioned in the previous paragraph. A heat source that can contribute significantly are the fan motors that run to circulate the air. Shortening the running times of the fan ensures less heat. On the other hand, air circulation is important to limit temperature differences in the room (and associated humidity differences). Therefore, temperature measurements in critical areas in the room should guide you in deciding whether fan running times can indeed be shortened. 100% circulation capacity of fans all the time is often not necessary. Thus, in most cases, circulation in between cooling actions can be reduced. This also brings you some energy savings.

Another heat source is due to air exchange with warmer outside air. Think of the ventilation system and the doorways. In rooms where doors are often opened, it is worth checking whether the number (and length) of openings, can be reduced. This limits the number of cooling actions.

Heat load can also result from automatic defrost systems when defrosting the evaporator. The number and length of the defrost cycle varies greatly in practice. Check whether this frequency and length is indeed needed. Of course there should not be any ice left at the end of the defrosting.

Water on the floor

A dry (concrete) floor in the storage room will absorb moisture from the air. Saturating the floor with water will counteract this process. Water can be added before the storage room is filled with product. A positive side effect is that the water can contribute to saturation of the warm air flowing over it. During the storage phase, the drained condense water from the evaporator is sometimes lead back to the storage room floor.

You have to ask yourself whether saturating the floor is actually needed and advantageous. The need for it will be less with a dense good-quality concrete floor. Please also note that dangerous ice floors can form at sub-zero temperatures.

Packaging materials

Storage usually takes place in plastic or wooden bins or cardboard boxes. Dry wooden storage bins can absorb significant amounts of water. For large bins (as shown in the photo below) this can be up to 2.5-3 kg water per bin. When a humid climate is desired, these bins can be moistened before filling. Also dipping of bins will moisten the wood. A good drain of excess water is then needed to avoid pools of water at the bottom of the bin. Otherwise, this can lead to rotten products in the lower layers in the bin.

The application of moisture barriers, such as plastic films or liners, also reduces water loss of the products. This should only be done when necessary, taking into account the downside when the atmosphere stays too humid.

Within our Postharvest Research programme we work on the influence of packaging and alternative techniques on product quality. In one of our packaging tests, we have stored packaged cluster tomatoes in crates in two layers. An example of this way of packaging can be seen in the photo below. The crates were placed at 14 °C for two days, followed by 7 days at 18 °C. We tested two varieties, and assessed weight loss (water loss) and quality. The water loss during this period differed between the varieties and there was also a striking difference between the two layers in the crate. Tomatoes in the lower layer had lost less water. However, this led to more mould growth on the green calyxes. An optimum should be found in minimizing water loss on the one hand and preventing mould growth on the other. In this case, it was found by creating a packaging solution in which a small airflow can move through the packaging and between the two layers.

Humidification systems

If the above measures are not applicable or do not have sufficient effect, humidification systems can be used as an additional tool. There are several systems to add moisture to the air. The use of these systems has its advantages and disadvantages. We describe these in our next article: Humidification in storage rooms.