How to maintain quality of fresh produce

Postharvest technologies are important tools, materials and services that help in maintaining the quality of the fresh produce. The following pages contain knowledge that is useful for companies that operate in the fresh supply chain, from farm to fork. If you need immediate consultation on one of the technologies, please contact us via the contact form.

Postharvest technologies and topics

Artificial Intelligence and Machine Learning

Would you catch an apple if someone gently throws it to you? And if the answer is ”YES”, would it be difficult? Would it involve solving a complex equation describing the motion of an apple in your mind in a fraction of second? In this topic page, we guide you through the main concepts AI and ML.

Blockchains and SOPs

Blockchain (Distributed Ledger Technology) is mainly known as the technology behind Bitcoins. However, it also has a beneficial use in supply chains, a topic that is highlighted on this page. It can contribute to strengthening the position of smallholders in developing countries. Anybody with a mobile phone can participate and register their trade data. It is a scalable technology and can make use of smart contracts for automated payments. The implementation of SOPs, standard operating procedures, in a blockchain-enabled supply chain is a golden combination.

Cold room design

The design of cold storage rooms varies a lot. The exact design depends on many aspects. Before a new room is built, many questions have to be answered. An important one is what temperature the room should be able to reach? Which cooling equipment is needed then? Should the room be suitable to cool down products that come in at high field temperature? It is interesting and useful to recognize the different elements of the cold room and know the reasoning behind it.

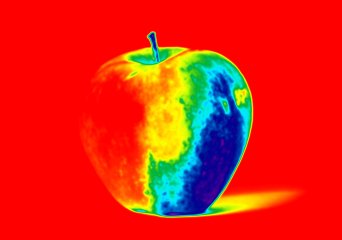

NIR technology

Non-destructive fresh fruit quality analysis is of wide interest to stakeholders involved at various stages of fresh fruit chain. The need for quality assessment ranges from decision-making during harvest to monitoring fruit ripeness during long-term storage at high-end fruit storage warehouses. Several non-destructive sensing techniques are available for the quality analysis of fresh products. A key technique being promoted as useful in practice is visible (VIS) and near-infrared (NIR) spectroscopy

Omics

A harvested fresh product is alive, meaning that it is still biologically active. Each living product consists of lots of cells in which all kinds of processes take place. In response to external factors, such as light, temperature and oxygen availability, cells react by making copies of parts of their DNA that will help them respond to these external factors. For example, in response to ethylene, they respond by ripening. They do this by copying sections of DNA related for example to cell wall degradation (fruit softening) or to chlorophyll breakdown (changing colour from green to yellow). The processes on this cellular level can be studied, usually with the purpose to make a link between a micro cellular process and a macro fruit process. This field of studies is called 'Omics'. Omics disciplines give an overview of the processes that occur within a product on a molecular level.

Phytosanitary treatment: CATT

Phytosanitary treatments are measures taken to control crop diseases and infections. They may be necessary before import/export can take place. On this page, we discuss the application of CATT, controlled atmosphere temperature treatment, as a new approach to phytosanitary treatment of fresh products.

Refrigerated transport

Refrigerated transport is an important link in fresh supply chains. The topic covers maritime transport and road transport. Maritime transport is performed with reefer containers, road transport ranges from semi-trailer to minivan. Although the purpose is the same: transporting the fresh products with minimum quality loss, the transportation method requires different background knowledge.

Packaging of fresh produce

Packaging is commonly used for transport, storage and sale of perishable products. It is a broad concept that can be applied to a single product (e.g. fresh-cut vegetables) or to consolidate a bulk product (e.g. cardboard boxes on a pallet). Packaging is not used solely for marketing reasons, a packaging concept fulfils one or more specific functions essential for the preservation of perishable products. The extended distribution chains and the many different processing methods applied to perishable products are only possible thanks to the use of packaging concepts.

Refrigerants in postharvest refrigerating systems

Refrigerants in postharvest refrigerating systems are used to create the temperature difference needed to transport heat from the cold storage room to the warm outside. The choice for the most optimal refrigerant is mostly based on safety (product, environment and people), refrigerating capacity and temperature level(s) of the refrigerating system for its application in the fresh chain. Every refrigerant has its specific characteristic in efficiency in range of temperature / pressure, ozone depleting factor, global warmth potential, safety (explosion, fire, pressure, health) and many more.