Doing quality measurements

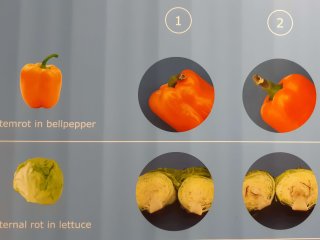

Extensive quality evaluations are carried out at various points in the fruit and vegetable chain. Different markets require different quality criteria. Examples of these quality criteria are a specific colour, size, firmness and sugar content. Quality can be measured non-destructively (by looking, feeling, sizing, smelling) or destructively (by cutting, tasting, grinding). Quality measurements include both external and internal properties. External quality measurements are usually focused on size and shape, colour, physiological disorders and diseases. Examples of internal quality measurements are firmness, sugar content, acidity, flavour, and disorders and diseases.

Destructive quality measurements

Different methods for analyses of fruit and vegetable quality exists. Well-known measurement methods are measurement of soluble solids content (SSC) after juicing and measurement of firmness with a penetrometer. These methods are easy to perform under the condition that the right protocol is followed.

Unfortunately these mentioned methods are destructive for the fresh product. Consequently only a sample of produce can be measured. It is therefore very important that the sample is representative of the whole batch.

Non-destructive quality measurements

Non-destructive quality measurements of fruit and vegetables can be helpful to measure external and internal properties. It has the great advantage over destructive measurements that products can still be sold after inspection. In this way, it facilitates the grading of products based on their size, shape, maturity or ripeness.

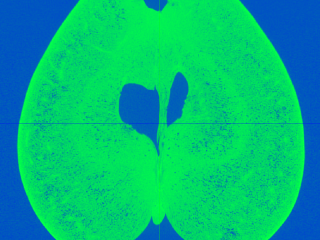

Among the techniques used are vision systems and near infrared spectroscopy (NIR). In addition to NIR devices in sorting lines, several hand-held NIR devices are available. Handheld devices can also be used in the field to measure fruit maturity. A very interesting development is NIR hyperspectral imaging which provides spectral data as a set of images.

Sample preparation

Equipment preparation

Colour measurements

Size and shape measurements

Firmness measurements

Measure Soluble Solids Content

Measuring starch

Titratable acid measurements

Measure the % dry matter

Measuring the sensory quality