Transport practices for papaya

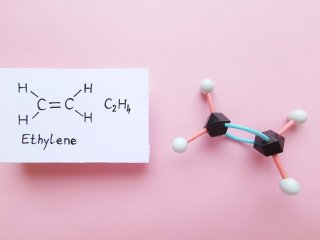

Many aspects are important when transporting papaya towards their final destination. One of them is maintenance of roads to minimize mechanical damage during transport. Careful loading of trucks to prevent fruit movement and collapse, using good shock absorbers and low-pressurized tires. Another aspect is avoiding transport of papaya with ethylene-producing or sensitive commodities and ensuring the fruit has uniform ripeness stages. Refrigerated trucks and air transport should regulate temperature according to ripeness to prevent chilling injury and maintain > 95 % relative humidity to reduce water loss.

Optimal transport conditions

At the packing house, the papaya is graded and packaged for market delivery. Papaya, harvested fresh, undergoes local processing practices tailored to the end user and market delivery timelines. Rapid transport to the market is crucial. Long-haul transportation of papaya typically involves air travel from major exporters such as Mexico, which exports mainly to the US and Canada, and Brazil, which exports primarily to Europe.