The melon chain

Practices in each step of the fresh chain have a great influence on the postharvest quality and shelf-life of fruit and vegetables. This also holds for melon. Harvest and cold chain must be well managed to reach the expected melon quality by the consumer. By using appropriate harvest processes and chain conditions, quality can be maintained longer and shelf life can be extended. Failure to follow these processes may result in a high degree of loss or deterioration of the product to a lower quality class. Every step in the chain is important for success later in the chain.

Aim for high quality at each step of the chain

Melons are available all year round thanks to the production in different countries. Among the largest producing and exporting countries are Spain, Mexico, Brazil and USA. Melons are harvested when mature, but not ripe. Ideally, the packhouse is just a short distance from the harvest fields. This minimizes the risk on damage during transport and facilitates early cooling in the packhouse. Soon after arrival at the packhouse, processes such as washing, grading and packing start. After pre-cooling, a proper loading in refrigerated trucks or reefers is important to maintain good temperature conditions during transport. It is of utmost importance to have a correct handling by all supply chain actors from the moment of harvest to deliver quality at moment of purchase and consumption by the end customer.

Steps in the melon chain

Melon types

The two broad categories of melon are muskmelons (C. Cucumis melo) and watermelons (C. Citrullus lanatus). Muskmelons have a thick skin and hollow fruit center containing loose seeds and fibers. Some of the most common varieties are Galia, Honeydew, Cantaloupe, Charentais and Piel de Sapo. One of the differences is the skin which can be smooth (like Honeydew), ribbed (like Cantaloupe) or netted (like Galia). The watermelons have (almost) uniform flesh without hollow fruit center. The seeds, if any, are embedded in the flesh.

Importance of optimal climate conditions in the chain

-

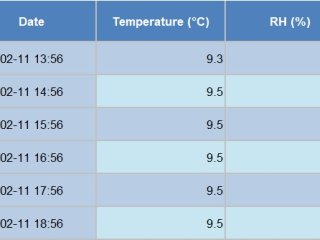

Temperature logging during transport. Photo by WUR. Temperature management

It is essential that melons, especially for overseas shipment, are cooled as soon as possible. Lowering the fruit temperature delays ripening, minimizes fruit water loss and slows decay. However, melons are susceptible to chilling injury that would lead to damages and flavour loss. Therefore they should not be stored too cold. Storage in the packhouse and transport from the packhouse to final destination must be properly temperature-controlled. -

Controlled Atmosphere (CA)

An optimal temperature is the first requirement to maintain good quality melons. In addition, the storage life can be extended by applying Controlled Atmosphere (CA) storage. The optimal CA conditions differs between varieties. Suboptimal O2 a CO2 conditions should lead to discoloration of flesh or skin and off-flavour. The ripening delay by CA is usually not enough to be economical in all situations. -

Melons in modified atmosphere (MA) packaging. Photo by WUR. Modified atmosphere (MA) packaging

Modified atmosphere (MA) packaging is available as bag in box. Packaging in special closed (polythene) bags will create a modified atmosphere (MA). This can only be a modified humidity, or a combination with changed O2 and CO2 conditions. A combination of good (pre-)cooling and increased CO2 percentage should inhibit mould growth. However, improper (pre-)cooling can have an adverse effect on the MA conditions.