Longread

Blueberry quality management

Without doubt blueberries became worldwide popular among consumers in the last decade. Consider the healthy image that blueberries have developed, add the high convenience level (easy-to-shack fruit) and it is not surprising that the sales of blueberries have exploded in the last 10 years. The increasing supply and demand dynamics bring huge challenges in managing blueberries quality after harvest.

Supply and demand of blueberries is increasing

Blueberry sales have gone up worldwide in the past ten years. In Europe, a growing supply will most likely continue to drive the consumption of blueberries. Moreover, the berries are not only trendy on the American and European continents, but are becoming more and more popular in China as well.

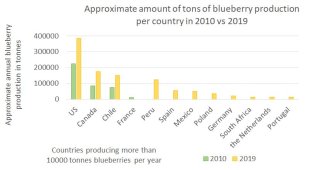

The current market pushes the international blueberry production, hence boosting availability for consumers and driving worldwide demand. The annual production numbers show this trend clearly: whereas in 2010 only 4 countries produced more than 10,000 ton blueberries per year, in 2019 the number of countries producing above 10,000 ton per year was 11. This reflects the continuous growth in blueberries production that started increasing in 2012 and has not slowed down yet to this date. The 4 largest producing countries in 2010 were The United States (224,000 tons), Canada (84,000 tons), Chile (76,000 tons), and France (11,000 tons). Peru is probably the most striking country showing an impressive increase in production to nearly 125,000 ton blueberries in 2019. The country became the fourth largest producer in the world. The United States were in volume still the leading producing country in 2019. However, in terms of value Peru was the world largest exporter in 2019.

Postharvest quality challenges

The increasing supply and demand dynamics bring huge challenges in managing blueberries quality after harvest. Year-round supply is currently achieved through the geographical segregation of production and relies on global logistics to ensure timely and efficient (long) distance distribution from producers to consumers.

Additionally, consumers and retailers demand high quality blueberries: crunchy, juicy, sweet, aromatic, uniform appearance/size and free of rot and bruises. These quality features are strongly dependent on cultivar, influenced by cultivation practices as irrigation, fertilization and crop protection measures and affected by transport/storage duration and conditions. Although blueberries are climacteric fruits, the eating quality of these fruits does not improve after harvest. As such, blueberries should be picked at a near to full ripe stage, which makes quality management all the more delicate. In addition, variations in cultivars and growth conditions result in considerable quality variations between batches of blueberries at the end of the chain both by retailers and consumers. In order to manage blueberry quality and avoid unnecessary losses in the supply chain, good practice guidelines are key.

Transport and storage conditions

Research into effects of temperature, relative humidity and gas conditions have shown that firmness, weight loss, total soluble solids content (° Brix) and ethylene production are strongly affected by transport and storage conditions. Blueberries are not cold-sensitive and therefore can be transported and stored between -1 and 1°C. Application of low temperatures reduces weight loss, ethylene production, and delays senescence. Particularly, the decreased solubilization rates of pectin and hemicellulose contribute to slow down the softening rate that starts already after harvest.

Textural changes during regular air atmosphere storage for 6 weeks at 2°C include the decrease of elasticity, leading to loss of crispness and crunch. Furthermore, berries can become gummy, mealy and lose flavour. Under controlled or modified atmosphere conditions (CA or MA, respectively), elevated CO2 may contribute to suppress fungal decay and delay softening. However, concentrations above 15-20% will lead to loss of flavour and off-odour formation. Application of reduced O2 levels (down to 6%) may maintain quality by suppressing ethylene production and decreasing the rate of ripening.

The extend of these effects depends, however, on several factors such as the maturity of the berries at harvest. Further research is necessary to define in which situations the application of high CO2 and low O2 concentrations, in combination with cultivar, harvesting strategy and production period deliver enough quality and shelf life improvement.

Ethylene plays an important role in the quality and shelf life of several fruits. Blueberries are not an exception. High amounts of ethylene have a negative effect on quality as this plant hormone increases fruit senescence without improving the berries flavour development. In addition, mold growth (Botrytis cinerea) can be stimulated in the presence of ethylene. In summary, special attention is needed to the presence of ethylene during transport and storage. Regarding the application of ethylene inhibitors as 1-methylcyclopropene (1-MCP), there is not yet a common understanding on the effects of this postharvest treatment in the current distribution chains.

Basic quality management measure

As discussed above there are several factors influencing the quality of blueberries. However, there is at least one postharvest measure that should always be applied to manage the quality of blueberries throughout the chain: fast cooling upon harvesting to remove the field warm. Blueberries should be cooled down as quickly as possible (preferably within 1 hour) with air forced cooling. Further handling of the berries (grade, sorting and packaging) should be performed under 10°C and the berries should be kept refrigerated (0-3°C) until consumption.