Packhouse practices for avocado

Packhouse practices cover the activities from the moment the products arrive in the packhouse to the moment of transport/export to the intended market. Sorting, grading, packing and cooling are among the main activities. For avocado as well as for many other fruit, it is very important that the packhouse has sufficient capacity to cool down the products; as good temperature management is a requirement to maintain a good quality of horticultural produce. Furthermore, proper cleaning and sanitizing of building and equipment is part of good packhouse practices.

Processing avocados in the packhouse

The processing of avocados at the packhouse facility must be well regulated and controlled. The process of sizing and grading is usually carried out through an automated system, such as roller conveyors with adjustable speed, but always well supervised. Cooling of the products should follow immediately. Forced air cooling is an effective tool to quickly lower the fruit temperature. However, avocados should not be stored below their critical temperature, as chilling injury may then occur which would result in risks on discolourations of skin and flesh and poor flavour.

Activities in the avocado packhouse before packing

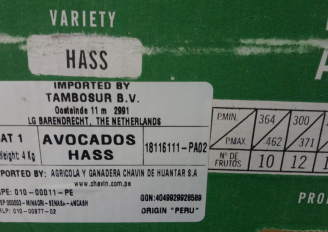

Activities in avocado packhouse from packing onwards

Ripening of avocados

Some packhouses (often present at importers) have ripening facilities. These are important to trigger the ripening of avocado and deliver ready-to-eat fruits to supermarkets. The ripeness level at the start and temperature management are critical for the ripening. The exact ripening program is supervised by experienced experts. Special (forced-air) ripening rooms are used to achieve and maintain an uniform fruit temperature of, for example, 20 °C. The fruit is monitored to decide when to stop the ripening process. Exposure to ethylene can be an additional tool to speed up the ripening.

"Consistency in quality is very important. The client must be able to rely on receiving the quality they expect"